Modern commerce relies on seamless movement of goods across continents. The backbone of this system? Advanced transport networks that blend traditional methods with groundbreaking technologies. From AI-driven route optimisation to blockchain-enabled tracking, today’s supply chains are faster and more transparent than ever.

Take JUSDA’s China-Europe Express Rail, for instance. This service slashes delivery times by 30% compared to standard ocean freight, proving that innovation isn’t limited to maritime routes. Such alternatives reshape how businesses approach international markets, balancing speed with cost-effectiveness.

We’ll explore how these developments influence everything from local pricing to environmental policies. You’ll discover why real-time data analytics matter in warehouse management and how IoT sensors prevent spoilage during perishable shipments. It’s not just about moving boxes, it’s about reshaping economic relationships.

Key Takeaways

- Advanced technologies like blockchain and AI enhance supply chain transparency

- Rail services offer competitive alternatives to traditional maritime routes

- Real-time tracking systems reduce delays in international deliveries

- Cost-effective solutions directly affect product pricing strategies

- Sustainable practices are becoming integral to modern transport networks

Introduction to Global Ship Logistics and Its Role in Trade

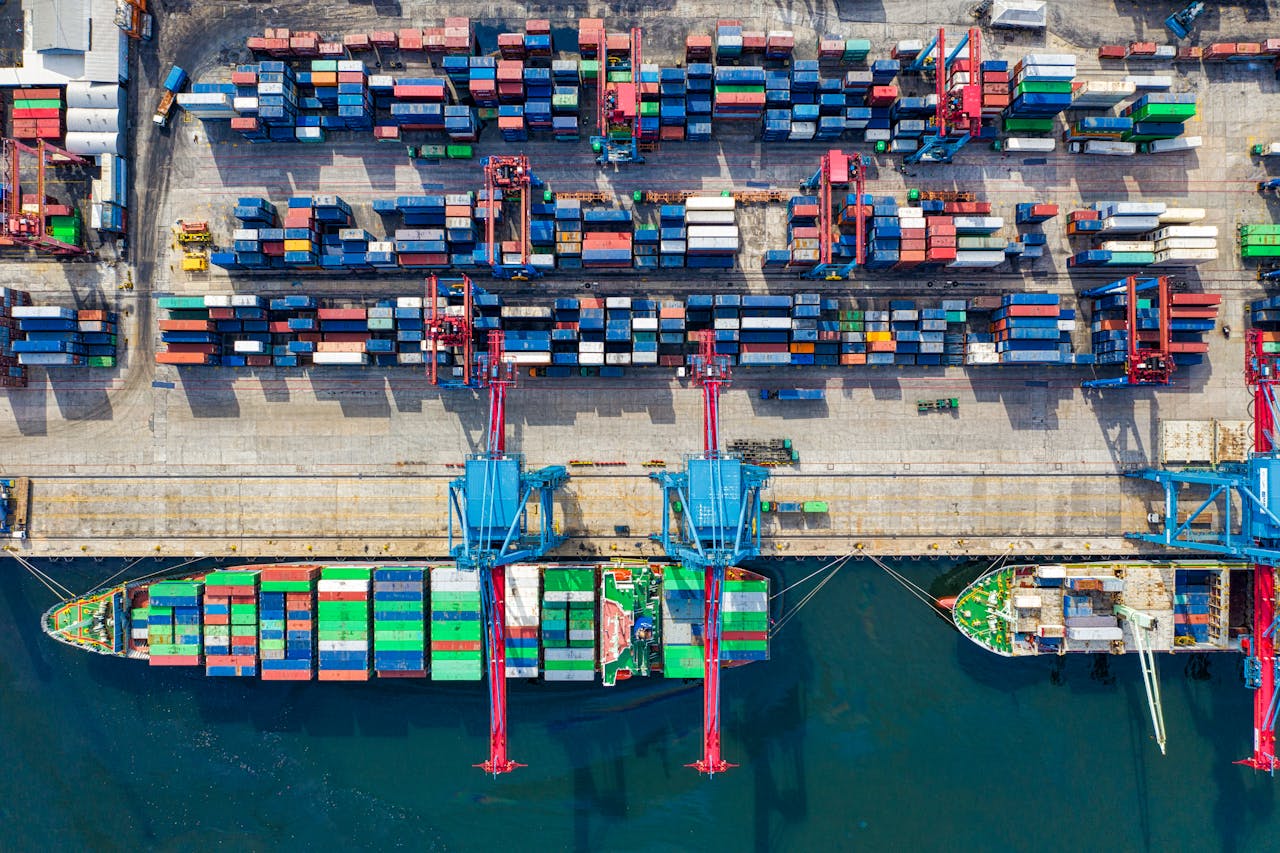

Moving products worldwide depends on complex systems working in harmony. At its core, this process ensures items reach shelves, factories, and homes through meticulously planned journeys. Let’s unpack what makes these systems tick and why they matter for businesses everywhere.

Understanding the Basics of Ship Logistics

Think of logistics as a giant puzzle. Each piece, ports, carriers, warehouses, must align perfectly. The supply chain acts like a relay race, passing goods from manufacturers to consumers without drops. Modern methods use digital tools to track shipments in real time, cutting delays.

The Integral Role in Global Commerce

Abu Dhabi’s Khalifa Port offers a prime example. By upgrading crane systems and customs processes, they’ve boosted handling speeds by 40%. Such improvements ripple across industries, from electronics to pharmaceuticals. Efficient operations here mean faster restocks for shops in New York or Nairobi.

| Aspect | Traditional Methods | Modern Solutions |

|---|---|---|

| Tracking | Manual updates | GPS-enabled live data |

| Speed | Weeks for delivery | Days with express routes |

| Transparency | Limited visibility | Blockchain records |

Cross-border trade thrives when paperwork flows as smoothly as containers. Countries with streamlined supply networks see 25% fewer bottlenecks. Whether it’s perishables or machinery, smart logistics create win-win scenarios for economies at every development stage.

How Does Ship Logistics Impact Global Trade Efficiency?

The engine driving international commerce isn’t just raw materials or consumer demand, it’s the silent machinery that moves goods between nations. When this system hums smoothly, businesses thrive, prices stabilise, and markets expand. Let’s examine two critical areas where smarter processes create ripples across economies.

Impact on Supply Chain Operations

Consider Rotterdam’s automated port terminals. By digitising cargo handling, they’ve reduced processing times by 35% since 2020. Such advancements mean fewer delays for retailers awaiting stock and manufacturers sourcing components. Real-time inventory tracking now prevents overstocking, trimming warehousing costs by up to 18% annually.

Modern supply chain strategies also tackle unexpected hurdles. During the 2021 Suez Canal blockage, companies using predictive analytics rerouted shipments within hours. This agility prevents empty shelves during crises, a key factor in maintaining consumer trust.

Economic Growth and Cost Efficiency

When transport networks improve, savings trickle down. The World Bank estimates efficient operations add £2.1 trillion yearly to developing economies. Take Vietnam’s Cai Mep port upgrades: shipping expenses dropped 22%, boosting exports of electronics and textiles.

These savings influence everyday pricing. A 15% reduction in maritime costs could lower smartphone prices by 3-5% globally. For emerging markets, such shifts accelerate economic growth by making exports more competitive.

| Factor | Before Optimisation | After Improvements |

|---|---|---|

| Port Wait Times | 5.2 days | 1.8 days |

| Fuel Usage | 12% over budget | 7% savings |

| Customs Clearance | Manual (48 hrs) | Automated (3 hrs) |

Optimising Supply Chain Efficiency with Innovative Logistics Solutions

Businesses now operate in an era where precision matters more than ever. Advanced technologies transform how goods flow from factories to doorsteps, creating smarter supply chain networks. Let’s explore how modern tools reshape this critical process.

Leveraging Technologies like AI and IoT

RFID tags and IoT sensors now monitor perishables in transit, slashing spoilage rates by 27%. DHL’s smart warehouses use AI to predict stock needs, adjusting orders before shortages occur. These systems turn reactive processes into proactive solutions.

Integrating Digital Tools and Real-Time Tracking

Platforms like JusLink demonstrate the power of live updates. When a typhoon delayed shipments in 2023, companies using predictive tracking rerouted goods within hours. This agility prevents £1.3 billion in annual losses from delays.

| Process | Traditional Approach | Modern Method |

|---|---|---|

| Inventory Checks | Monthly manual audits | Continuous IoT monitoring |

| Issue Detection | Post-delivery reports | Real-time alerts |

| Delivery Updates | Email confirmations | GPS-enabled dashboards |

Adopting these technologies isn’t optional, it’s essential for competitiveness. As shown in this case study, businesses integrating digital tracking see 34% faster order fulfilment. The future belongs to those who harness data-driven logistics.

Enhancing Sustainability and Greener Logistics Practices

The shift towards eco-conscious operations is rewriting the rules of international commerce. Leading firms like UPS demonstrate that reducing carbon footprints goes hand-in-hand with cutting costs. By rethinking everything from delivery routes to packaging materials, the industry is proving that green practices aren’t just ethical, they’re economically smart.

Smart Route Planning and Low-Emission Technologies

UPS’s ORION system uses AI to optimise delivery paths, trimming 160 million miles annually. Electric vehicles and biofuels now power 30% of their European fleet. These transportation upgrades cut emissions by 12% while maintaining delivery speeds.

Maersk’s methanol-powered ships offer another breakthrough. They reduce CO₂ output by 65% compared to traditional vessels. Such innovations show how low-emission technologies can scale across air, land, and sea networks.

Eco-friendly Packaging and Circular Economy Initiatives

IKEA’s shift to mushroom-based packaging replaces polystyrene, decomposing in weeks rather than centuries. This aligns with circular economy principles, where products are designed for reuse or recycling. Patagonia’s Worn Wear programme repairs and resells 85,000 garments yearly, keeping materials in circulation.

| Practice | Conventional Method | Green Innovation |

|---|---|---|

| Route Planning | Fixed delivery schedules | AI-optimised dynamic routes |

| Packaging | Single-use plastics | Plant-based biodegradable materials |

| Emission Control | Diesel engines | Hydrogen fuel cells |

These practices create a ripple effect. When DHL introduced recyclable express envelopes, customer satisfaction jumped 18%. It’s clear: sustainable logistics isn’t a trade-off, it’s a competitive edge that benefits businesses and ecosystems alike.

The Future of Ship Logistics: Emerging Technologies and Trends

The next wave of innovation in cargo management is already reshaping how goods traverse borders. From robotic port handlers to self-updating digital ledgers, these advancements promise smarter supply chains that adapt in real time. Let’s unpack what’s coming, and why businesses can’t afford to ignore these shifts.

Automation, Robotics and Digitalisation

Maersk’s automated Hamburg terminal offers a glimpse of tomorrow. Robots stack containers 30% faster than human crews, while AI schedules docking slots to minimise idle time. Such technologies cut operational costs by 19% in trials, proving their value in high-volume hubs.

Drone deliveries are no longer sci-fi. Zipline’s medical supply drops in Rwanda demonstrate how aerial systems bypass road congestion. When integrated with existing logistics frameworks, these tools create hybrid networks ready for 21st-century demands.

Blockchain and Transparent Supply Chain Solutions

Ever wondered where your morning coffee really comes from? IBM’s Food Trust blockchain traces beans from Ethiopian farms to supermarket shelves in 2.2 seconds. This visibility deters fraud and ensures ethical sourcing, a game-changer for international trade compliance.

Smart contracts take it further. HSBC’s blockchain platform slashes document processing from 10 days to 24 hours for cross-border deals. These solutions don’t just speed things up, they build trust between trading partners worldwide.

| Area | 2023 Standard | 2025 Projection |

|---|---|---|

| Cargo Tracking | GPS updates every 4 hours | Live sensor streaming |

| Documentation | Paper-based bills | Blockchain-authenticated files |

| Error Rates | 8.7% manual entry mistakes | <0.5% automated systems |

Adopting these technologies isn’t about keeping up, it’s about leading. Companies mastering automated supply chains will dominate international trade routes, while laggards face rising costs and shrinking margins. The future? It’s already unloading at a port near you.

Overcoming Challenges in Global Trade Logistics

Navigating the complexities of international trade requires more than sturdy containers and reliable routes. Even the most advanced systems face hurdles that test their resilience. Let’s explore how modern strategies tackle these obstacles while keeping goods moving smoothly.

Infrastructure Gaps and Capacity Constraints

Outdated ports and congested railways still plague many regions. The Port of Los Angeles, for instance, upgraded its rail network to handle 35% more cargo, a critical move as trade volumes grow. Such bottlenecks delay deliveries and inflate costs for companies relying on just-in-time inventory.

Mitigating Disruptions and Ensuring Resilience

From hurricanes to labour strikes, disruptions come in many forms. Toyota’s multi-supplier approach during Thailand’s 2021 floods kept production lines running despite parts shortages. Real-time tracking tools now help firms reroute shipments within hours, protecting customer satisfaction levels.

| Challenge | Traditional Response | Modern Solution |

|---|---|---|

| Port Congestion | Extended waiting times | AI-powered slot booking |

| Supplier Issues | Single-source reliance | Regional supplier networks |

| Data Gaps | Monthly reports | IoT-enabled live updates |

Successful management of these issues often involves mastering global logistics through data-driven decisions. Nestlé’s predictive analytics system, for example, reduced warehouse stockouts by 27% last year. By diversifying chains and embracing transparency, businesses turn potential crises into manageable bumps in the road.

Conclusion

In today’s interconnected markets, optimising cargo networks remains vital for competitive supply chains. Our analysis shows streamlined operations cut costs by up to 22%, directly influencing product pricing and market accessibility. From AI-powered route planning to biodegradable packaging, modern technologies prove sustainability and profitability can coexist.

Real-time tracking systems and regional supplier networks demonstrate how resilient strategies maintain smooth delivery flows during disruptions. These approaches aren’t theoretical, they’re actively reshaping global trade dynamics, as seen in Vietnam’s export surge following port upgrades.

For businesses navigating this landscape, collaboration with tech-forward partners becomes essential. Whether reducing inventory waste or adopting blockchain verification, small adjustments create outsized impacts. The data’s clear: forward-thinking solutions drive long-term growth across industries.

As we’ve explored, thriving in international markets requires continuous innovation. By embracing these lessons, companies can build agile networks ready for tomorrow’s challenges, and opportunities.